How To Choose the Right Automotive Workbenches

The right automotive workbench can make all the difference in your workshop, acting as the backbone for tasks that demand precision and organization. Whether you’re a professional mechanic or an automotive enthusiast, a reliable workbench can boost efficiency by keeping your tools within reach, providing a sturdy surface for heavy-duty repairs, and ensuring safety while you handle intricate jobs. Beyond functionality, a well-chosen workbench helps you streamline your workflow, save time, and even extend the lifespan of your tools through better organization. Read on to learn how to choose the right automotive workbenches for your specific needs.

Understanding Automotive Workbenches

Automotive workbenches are specialized workstations designed to provide stable, organized, and efficient spaces for completing various automotive tasks. They serve as the heart of any workshop, offering secure surfaces where mechanics can perform jobs ranging from routine maintenance to detailed engine repairs. Beyond acting as a workspace, these workbenches often include built-in storage options that allow you to keep essential tools and supplies close at hand. By centralizing both tools and tasks, workbenches reduce the amount of time spent searching for equipment and improve overall workflow.

They are built to handle the unique demands of automotive work, often incorporating durable materials and features that withstand heavy-duty use. Whether it’s supporting heavy parts, accommodating precision tasks, or remaining sturdy during long hours of labor, automotive workbenches are a critical investment for both professionals and hobbyists looking to elevate their work quality.

Types

There are several types of automotive workbenches to choose from, each tailored to meet different needs. Fixed workbenches are a popular choice for permanent setups. These sturdy options often feature a robust frame and ample work surface, making them ideal for heavy-duty tasks. Portable workbenches, in contrast, are lightweight and designed for mobility, making them a go-to option for mechanics who work at multiple locations or prefer flexibility in their workspaces.

Modular workbenches take customization to another level, allowing users to configure them with additional storage panels, accessories, or extensions as their needs evolve. Each type has its own distinctive features, from locking wheels on portable versions to adjustable shelving on modular models. With such variety available, it’s easy to find a workbench that caters to specific space, task, and budget requirements.

Benefits

Each type of automotive workbench offers unique benefits that enhance how a workspace operates. Fixed workbenches deliver unrivaled stability and durability, which is especially useful for mechanics performing heavy or repetitive tasks. Their solid construction allows users to trust the benches to support the weight of large components and tools.

Portable workbenches provide much-needed flexibility for those who work in changing environments or share a single garage space. Their mobility ensures users can adapt the workspace to suit the task at hand or clear the area when needed.

Modular workbenches shine in terms of adaptability, giving users the freedom to expand or rearrange their setup as projects or tools evolve. All types contribute to better organization, improved workflow, and enhanced safety by providing a dedicated, clutter-free area to work on demanding automotive tasks.

Key Features To Look For When Investing In Workbenches

When choosing an automotive workbench, it’s crucial to focus on specific features that will meet your unique needs and workload demands. The right combination of features ensures you have a workspace that is efficient, safe, and built to last.

Durability

Durability is perhaps the most important feature to consider when selecting an automotive workbench. Automotive tasks often involve heavy parts, frequent use of tools, and exposure to harsh conditions, so your workbench must be built to withstand such challenges. A durable bench provides a stable foundation that won’t wobble or deteriorate under significant weight or pressure.

Look for construction materials like high-grade steel or solid hardwood, which are designed for long-term use. Reinforced legs and a strong frame can further enhance the bench’s overall strength. Durability also extends to resilience against spills, scratches, and impact, making sure your investment holds up well over time.

Size and Surface Space

When deciding on size, consider your available workshop area and the types of projects you typically handle. Larger workbenches offer expansive surface space for complex jobs, while compact models are ideal for smaller garages.

Surface space should also factor into how you work, as some workbenches offer extra-wide tops for multi-step processes while others include side extensions for added versatility. By choosing the right size and shape, you can create a functional workspace that optimizes both comfort and productivity.

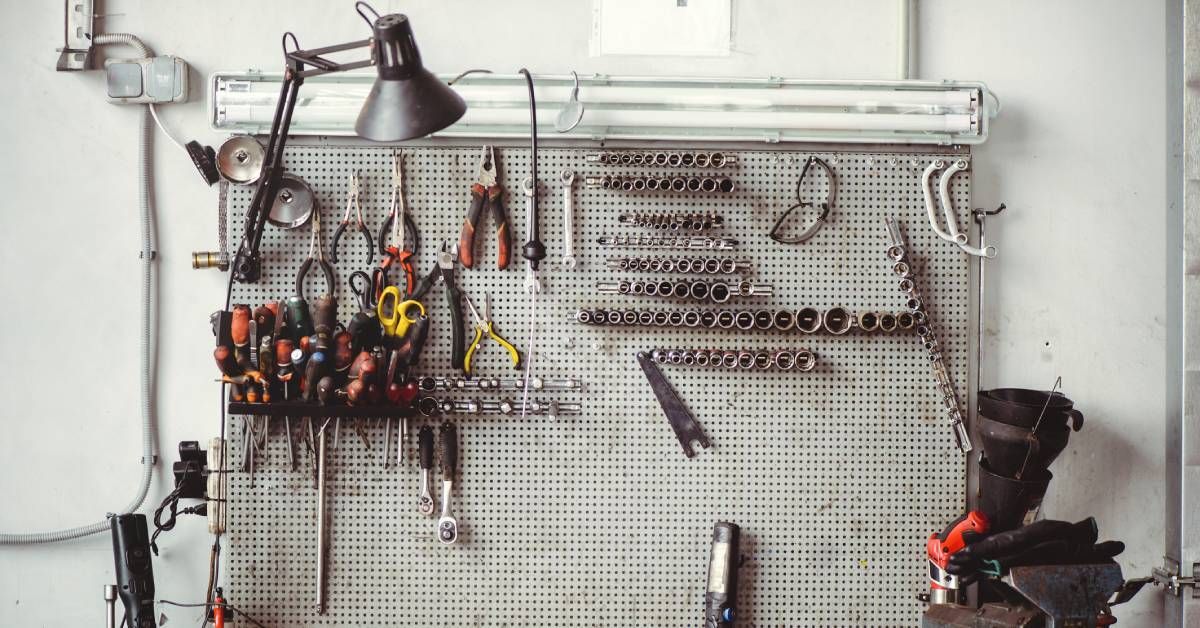

Storage Solutions

Storage is a game-changer when it comes to the functionality of an automotive workbench. Many workbenches are equipped with built-in drawers, shelves, or pegboards to help organize tools and accessories. These features reduce clutter in your workspace and ensure that essential tools are always within reach.

Adjustable storage solutions allow you to customize your bench to hold different tools as your collection grows. Having everything in one central location also saves time during projects, as you won’t have to search for items when you need them. By integrating effective storage options, a workbench boosts both organization and efficiency in your automotive tasks.

Built-In Adjustable Tools

Built-in adjustable tools can significantly enhance the functionality and efficiency of an automotive workbench. These features allow for quick access to essential tools that are seamlessly integrated into the workspace, eliminating the need for separate equipment and saving valuable space in the workshop. Adjustable components, such as height-adjustable clamps or tool mounts, provide versatility by accommodating a range of tasks and projects.

The ability to customize these tools ensures they fit your specific needs, making the workbench adaptable to different automotive jobs and user preferences. This combination of convenience and versatility transforms a standard workbench into a multi-purpose workstation, delivering added practicality and ease of use for both professionals and DIY enthusiasts.

Safety Features

Safety is paramount in any workshop, and your workbench should be designed with this aspect in mind. Features such as non-slip surfaces, rounded edges, and secure storage compartments can help prevent accidents. Lockable drawers or cabinets add an extra layer of security, especially if you work with hazardous materials or expensive tools.

Stability is another key consideration—a well-built workbench should remain steady even under heavy pressure or weight. Additionally, some workbenches offer integrated lighting or protective mats to enhance precision and safety during intricate tasks. By prioritizing safety features, your workbench becomes a secure foundation for worry-free automotive work.

Find a Quality Automotive Workbench at Tyler Supply

Knowing how to choose the right automotive workbench allows you to equip your workshop with a reliable, functional, and durable centerpiece that supports your tasks with ease. Whether you need a compact bench for tight spaces or a robust, heavy-duty model for demanding tasks, Tyler Supply’s selection offers something for every workshop. Explore our collection of automotive workbenches and enhance your operations today.